Project: 2001 1.8T Golf IV

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

Some assembly required.....

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

Some progress... all the big parts have been removed from the car so it is now time to put it all back together. The oil feed line to the turbo was the biggest PITA as it was impossible to get to.

Anyway, some stock vs. go-fast parts side by side.

The pile of 1.8T parts I took out yesterday.... my green Rabbit suspension makes for a nice frame.

I think it is very impressive the HUGE difference between the stock exhaust manifold and the ATP setup. Stock is tiny.

Anyway, some stock vs. go-fast parts side by side.

The pile of 1.8T parts I took out yesterday.... my green Rabbit suspension makes for a nice frame.

I think it is very impressive the HUGE difference between the stock exhaust manifold and the ATP setup. Stock is tiny.

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

The past two days were productive.

The FMIC has been installed and most of the plumbing is done. I did not connect the tubing to the intake yet as I need to change the throttle body from DBW to DBC. I have not installed the front bumper cover yet (will require some shaving). The installation was a bit of a pain… I had to cut the lip of the bumper bar so that IC would sit flush against the bottom of the bumper. Per ATP’s instructions, I had to cut the lower radiator support, but after I finished and reviewed the work, I have no idea why I had to cut it. The IC doesn’t hang anywhere near the radiator support. Looking again at ATP’s instructions, it looks like the IC in the directions is different than what I actually had to install. There was some wasted time. I cut part of the battery box base (I do not have the battery box anymore since it was a causality of the rollover) to make room for the pipes. I also had a little problem clearing the headlight (throttle body side), so I cheated by removing the back cover of the headlight for clearance.

IC mounted to the bumper/rebar:

I had to drill a hole all the way through the second layer just so I could see. Then I worked an open-end wrench with the nut duct taped to it over to the correct position. The photo is at a sharp angle so you can see the nut.

Mount on the car with the tubing. I had to put the tow hitch at an angle (I want to leave it mounted on the car)

The removal of the old turbo was very difficult with the “you can’t see them, but they’re there” oil/coolant lines and miscellaneous bolts/nuts. Installation of the new oil/coolant lines looks like it will be much easier since I can see all the connections because the turbo doesn’t hang below the exhaust manifold.

Installation of the ATP manifold was a royal PITA since it was impossible to see the nuts and even move impossible to (a) get an open-ended wrench on the nuts and (b) to be able to swing the wrench to tighten the nut. Well, I don’t think Sears will take back my 12mm combo wrench after I shaved it down to make it thinner both in depth of the wrench and the thickness of the round part. I also bent the wrench to allow for the swing. It actually worked quite well. I wish I had thought of it before (as does my friend Nick) since Nick tighten (mostly) the hard to get nuts with the open-end wrench over the course of an hour. I just had to tighten them with the modified wrench.

Hard to see/work with nuts:

The fabrication:

I hung the turbo last night. Good thing I didn’t start tighten the top nuts because one of the bottom nuts required the turbo to be at the end of the stud to be able to fit the nut between the turbo housing and the top of the stud. I was able to tighten all but one of the nuts since I needed a 12mm combo wrench. Hmmmm, somehow my 12mm got bent and didn’t work here.

Turbo partially installed:

The nut that had to be installed first (lightened area) and the nut next to it (left side of image) that I couldn't tighten without a straight 12mm wrench):

The turbo from the bottom:

Hopefully tonight I will be able to install the oil and coolant lines and complete the intercooler pipes. That leaves Wednesday night to install the FPR, injectors, and BOV. If there is time, I get the exhaust completed.

EDIT: Didn't get a chance to work on the car tonight due to an SCCV meeting followed by the gym.

The engine management should be in the mail to me today. Hopefully I will be able to get that on by Monday (busy this weekend drinking that 1/2 barrel of Switchback).

I need to get to Fast Addiction to pick up some last minute items.

The FMIC has been installed and most of the plumbing is done. I did not connect the tubing to the intake yet as I need to change the throttle body from DBW to DBC. I have not installed the front bumper cover yet (will require some shaving). The installation was a bit of a pain… I had to cut the lip of the bumper bar so that IC would sit flush against the bottom of the bumper. Per ATP’s instructions, I had to cut the lower radiator support, but after I finished and reviewed the work, I have no idea why I had to cut it. The IC doesn’t hang anywhere near the radiator support. Looking again at ATP’s instructions, it looks like the IC in the directions is different than what I actually had to install. There was some wasted time. I cut part of the battery box base (I do not have the battery box anymore since it was a causality of the rollover) to make room for the pipes. I also had a little problem clearing the headlight (throttle body side), so I cheated by removing the back cover of the headlight for clearance.

IC mounted to the bumper/rebar:

I had to drill a hole all the way through the second layer just so I could see. Then I worked an open-end wrench with the nut duct taped to it over to the correct position. The photo is at a sharp angle so you can see the nut.

Mount on the car with the tubing. I had to put the tow hitch at an angle (I want to leave it mounted on the car)

The removal of the old turbo was very difficult with the “you can’t see them, but they’re there” oil/coolant lines and miscellaneous bolts/nuts. Installation of the new oil/coolant lines looks like it will be much easier since I can see all the connections because the turbo doesn’t hang below the exhaust manifold.

Installation of the ATP manifold was a royal PITA since it was impossible to see the nuts and even move impossible to (a) get an open-ended wrench on the nuts and (b) to be able to swing the wrench to tighten the nut. Well, I don’t think Sears will take back my 12mm combo wrench after I shaved it down to make it thinner both in depth of the wrench and the thickness of the round part. I also bent the wrench to allow for the swing. It actually worked quite well. I wish I had thought of it before (as does my friend Nick) since Nick tighten (mostly) the hard to get nuts with the open-end wrench over the course of an hour. I just had to tighten them with the modified wrench.

Hard to see/work with nuts:

The fabrication:

I hung the turbo last night. Good thing I didn’t start tighten the top nuts because one of the bottom nuts required the turbo to be at the end of the stud to be able to fit the nut between the turbo housing and the top of the stud. I was able to tighten all but one of the nuts since I needed a 12mm combo wrench. Hmmmm, somehow my 12mm got bent and didn’t work here.

Turbo partially installed:

The nut that had to be installed first (lightened area) and the nut next to it (left side of image) that I couldn't tighten without a straight 12mm wrench):

The turbo from the bottom:

Hopefully tonight I will be able to install the oil and coolant lines and complete the intercooler pipes. That leaves Wednesday night to install the FPR, injectors, and BOV. If there is time, I get the exhaust completed.

EDIT: Didn't get a chance to work on the car tonight due to an SCCV meeting followed by the gym.

The engine management should be in the mail to me today. Hopefully I will be able to get that on by Monday (busy this weekend drinking that 1/2 barrel of Switchback).

I need to get to Fast Addiction to pick up some last minute items.

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

The saga continues.

Big BOV... no idea where/how to install it.

The hairdryer installed...

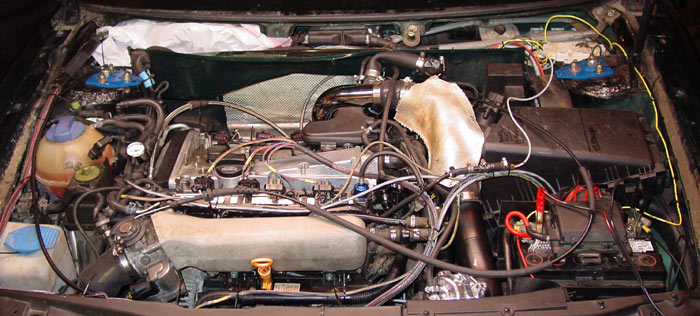

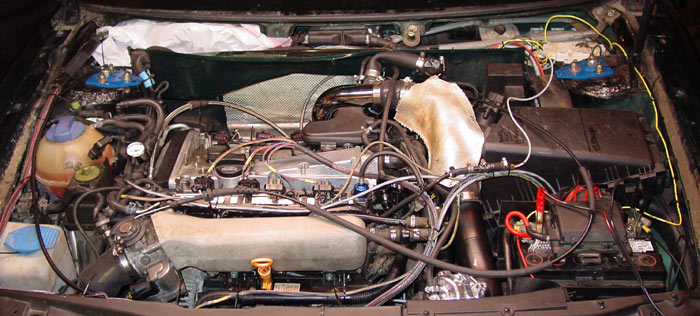

Engine... not all hoses connected yet.

-----------------------

Now I'm above my head....

How the car has been sitting for 5 weeks....

Package arrived today with some wires in it...

Starting to sort out/layout the harness. I plugged in what I could figure out so that I could determine the flow of the harness, and therefore, how/where to mount everything. A bit of a brick wall here so I have some deep thinking to do.

Letting the turbo breath with full 3" exhaust. Chris Achilles is doing the side exit for me.

Split race muffler... the muffler is 5" round and only 6" long.

Bigger is better...

Big BOV... no idea where/how to install it.

The hairdryer installed...

Engine... not all hoses connected yet.

-----------------------

Now I'm above my head....

How the car has been sitting for 5 weeks....

Package arrived today with some wires in it...

Starting to sort out/layout the harness. I plugged in what I could figure out so that I could determine the flow of the harness, and therefore, how/where to mount everything. A bit of a brick wall here so I have some deep thinking to do.

Letting the turbo breath with full 3" exhaust. Chris Achilles is doing the side exit for me.

Split race muffler... the muffler is 5" round and only 6" long.

Bigger is better...

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

Done. Car is down at Quintin's Brothers in Williston to get dyno tuned. They may or may not get to it today. The exhaust system didn't do a very good job of making the car quieter.... I think it sounds nice.

Joe from axismotorsport.com was making sure the 034EFI wiring harness was functional. It turns out that 034EFI did not include a mini-harness to allow the stock tach to work. Because the stock tach didn't work, the fuel pump wouldn't stay on and the oil warning light kept flashing.

Cyrus, Chris Marotti, and Chris Achilles came over later with the Achilles custom exhaust.

While Cyrus, Achilles and I worked trying to get the exhaust hung we got to listen to Marotti play us a ditty on the guitar. Much enjoyed!

I still need to do a better job with the after-market tach (temp fix until I get the missing harness) and boost (hack!) gauge (hack!) install (hack!!), but I think I'm all set now. Oh, and finish hanging the exhaust.

I think I got a total of 10 hours of sleep over the past three nights.

Pictures....

Joe from axismotorsport.com was making sure the 034EFI wiring harness was functional. It turns out that 034EFI did not include a mini-harness to allow the stock tach to work. Because the stock tach didn't work, the fuel pump wouldn't stay on and the oil warning light kept flashing.

Cyrus, Chris Marotti, and Chris Achilles came over later with the Achilles custom exhaust.

While Cyrus, Achilles and I worked trying to get the exhaust hung we got to listen to Marotti play us a ditty on the guitar. Much enjoyed!

I still need to do a better job with the after-market tach (temp fix until I get the missing harness) and boost (hack!) gauge (hack!) install (hack!!), but I think I'm all set now. Oh, and finish hanging the exhaust.

I think I got a total of 10 hours of sleep over the past three nights.

Pictures....

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

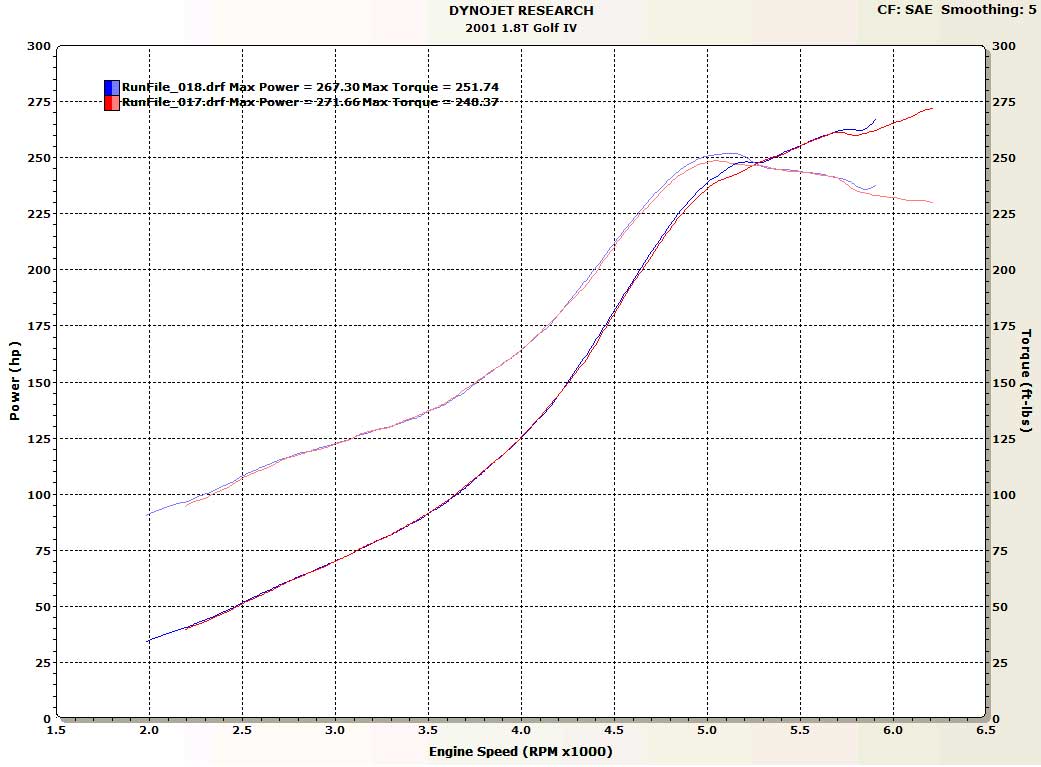

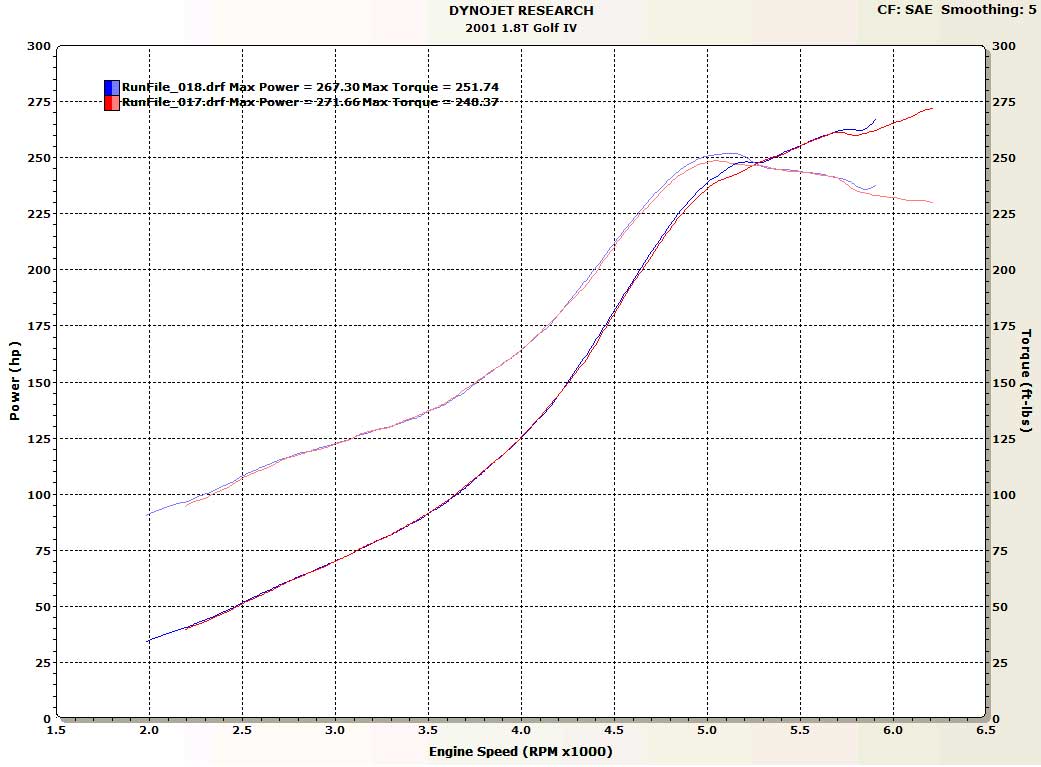

We still need to mount the ECU inside the car (it is in the rain tray at the moment), but this means I need to remove the wires on the left side of the car (driver's side for me) and relocate them along the right side of the car.

We had some problems with the car at Lime Rock (track event) where the spark plugs would foul (oil from PCV) and turbo would become loose. Issues that I will address this week as I have a hillclimb in two weeks. I also need to make it quieter.....

Photos and videos from its first track event will be forthcoming.

Due to the stock internals of the engine (building it over the winter), we stopped at 18 psi and got 277 wheel HP from it. The turbo can breath right up to 28-30 psi quite efficiently, but I want to keep the engine in one piece this summer. This will turn out an easy 400 crank HP when done and a GREAT power band (good low end and top end). Very pleased with the GT2871R!

Steve

We had some problems with the car at Lime Rock (track event) where the spark plugs would foul (oil from PCV) and turbo would become loose. Issues that I will address this week as I have a hillclimb in two weeks. I also need to make it quieter.....

Photos and videos from its first track event will be forthcoming.

Due to the stock internals of the engine (building it over the winter), we stopped at 18 psi and got 277 wheel HP from it. The turbo can breath right up to 28-30 psi quite efficiently, but I want to keep the engine in one piece this summer. This will turn out an easy 400 crank HP when done and a GREAT power band (good low end and top end). Very pleased with the GT2871R!

Steve

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

Brady at Quintin's (dyno shop) e-mailed me today to tell me how to use the program to view the results. I didn't realize that that graph x and y titles were clickable menus. I'm unsure which program I ended up with (both displayed), but it is a very conservative number (18 psi) to where we are going (28 psi +/-).

Fun for now and the engine should hold together just fine.

Fun for now and the engine should hold together just fine.

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

- Mr. Bridgestone

- Posts: 1454

- Joined: Sat Jun 26, 2004 12:21 am

- Location: Milton, Vermont

- Rabbit Farmer

- SCCV Board Advisor

- Posts: 5206

- Joined: Wed Jun 25, 2003 11:37 pm

- Location: Milton, Vermont

- Contact:

Hmmm... I do have one of those. I got it for my Rabbit. LOL

Steve #702

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar

My project post on VWvortex Rabbit Farmer projects

It takes hundreds of nuts to hold a car together, but it takes only one of them to scatter it all over the highway. - Evan Esar